TECHNICAL PARTS CUSTOM-MADE SOLUTIONS AND COMMITMENT TO QUALITY

Button-Fly Industry is contract manufacturer that provides single source responsibility for injection-molded thermoplastic, silicone, Metal& Machining and

membrane switch and assemblies.

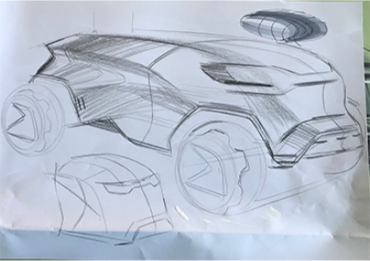

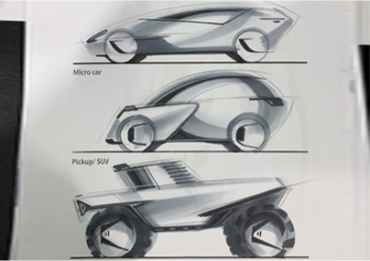

Product Development

Experience Innovation

Button-Fly Industry recognizes that many companies have

limited resources and budget constraints for developing

new products, or are in need of tooling expertise. This is

where our Product Development can help.

Innovation is in our DNA, which is why Button-Fly Industry

excels at product development and design for manufac

turing (DFM) support. We are strong believers that early

supplier involvement is critical to successful new product

introductions. Early supplier involvement allows our cus-

tomers to focus on their core competencies while we

focus on ours-putting years of experience to work design-

ing for manufacturability, improving product perfor-

mance, and reducing product cost and time-to-market. At

Button-Fly Industry, customers turn to us for more than

just product development, but solution development.

Design for Excellence

Design for Excellence (DfX) goes beyond just designing for

manufacturing. It includes the entire product lifecycle,

from development and production to sue and disposal.

Ensure proper product design, material selection, tool

design, supply continuity, and long-term product quality.

Avoid significant increases on project and unit cost, reduc-

ing long-term cost of goods sold.

Eliminate costly engineering changes and shorten overall

project timing.

Exceptional program Management

Getting your product to market quickly, efficiently

Formal requirements review, design review, and valida-

tion procedure

PD Capabilities

Concept development

Industrial design Product design and development

Design for DFM

Design verification and validation

Rigorous IP protection standards

PLASTICS PARTS

Delivering the right solution every time.

Button-Fly Industry excel at close-tolerance precision mold making, molding, and contract assembly geared towards design for manufacturing, innovative problem solving, and speed-to-market. Our goal become a leading supply chain partner to the world’s most successful companies in the healthcare, automotive, and consumer/industrial markets. We standardize equipment, system, and procedures at facility to ensure quality, maximize efficiency, and minimize costs.

Button-Fly Industry excel at close-tolerance precision mold making, molding, and contract assembly geared towards design for manufacturing, innovative problem solving, and speed-to-market. Our goal become a leading supply chain partner to the world’s most successful companies in the healthcare, automotive, and consumer/industrial markets. We standardize equipment, system, and procedures at facility to ensure quality, maximize efficiency, and minimize costs.

Plastic manufacturing capabilities:

Advanced in-house precision mold making expertise

Cost-effective quick-turnaround prototypes

Precision thermoplastic injection molding and assembly

Application-specific material selection consultation

Multi-shot, multi-material molding

Multi-component and multi-purpose devices

Micro-molded components

Medical packaging

Electronic components

Molded filter cores, cages, and end caps

Electronic device plastic enclosures

Functional IP components

Sensor, actuator, and control module components

Secondary treatment:

Plastic part surface coating, silkscreen printing

Plasic part surface laser etching

Plastic Ultrasonic welding

Parts and parts house assembly

INJECTION TOOLING EXHIBITION

PLASTIC PRODUCT EXHIBITION

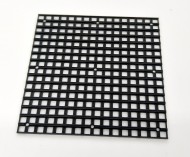

SILICONE

Experience Lets Us Rethink What’s Possible, Then Deliver It

Button-Fly Industry Silicones delivers cost-effective, single-source solutions for both precision Liquid Injection Molding (LIM) and compression solid Rubber/Silicone components and assemblies for the Healthcare, Automotive, and Consumer/Industrial markets. Silicone is used in many mission-critical applications where failure is not an option. Experience in preci- sion tight-tolerance components with exceptional shot-to-shot repeatability and commitment to best quality manufacturing continue to make Button-Fly Silicones the supplier of choice

Button-Fly Industry Silicones specializes in application-specific material selection, product design and development, in-house precision tooling, plus conventional silicone compression molding and advanced Liquid Injection Molding (LIM) technologies designed to eliminate waste and ensure the highest quality products. Along with a variety of contract manufacturing services such as heat curing, sterilization, assembly, pad printing, surface coating, laser etching and packaging. Button-Fly Industry Silicones is a trusted partner for quick prototypes, flawless launch, and reliable continuous production.

Button-Fly Industry Silicones delivers cost-effective, single-source solutions for both precision Liquid Injection Molding (LIM) and compression solid Rubber/Silicone components and assemblies for the Healthcare, Automotive, and Consumer/Industrial markets. Silicone is used in many mission-critical applications where failure is not an option. Experience in preci- sion tight-tolerance components with exceptional shot-to-shot repeatability and commitment to best quality manufacturing continue to make Button-Fly Silicones the supplier of choice

Button-Fly Industry Silicones specializes in application-specific material selection, product design and development, in-house precision tooling, plus conventional silicone compression molding and advanced Liquid Injection Molding (LIM) technologies designed to eliminate waste and ensure the highest quality products. Along with a variety of contract manufacturing services such as heat curing, sterilization, assembly, pad printing, surface coating, laser etching and packaging. Button-Fly Industry Silicones is a trusted partner for quick prototypes, flawless launch, and reliable continuous production.

Silicone Rubber Capabilities:

Design for Excellence (DfX) including DFM product development

Silicone keypad design and tooling

Fast and economical prototyping with production-representative tooling

Advanced LSR mold-making expertise and full in-house production capability

Multi-shot and multi-material molding for enhanced product functionality, lower cost, and improved quality

A broad portfolio of secondary operations such as heat curing, sterilization, assembly, pad printing, epoxy coating, PU coating, laser etching and packaging

Contract manufacturing services for single-source production and project coordination

SILICONE PARTS& KEYPAD EXHIBITION

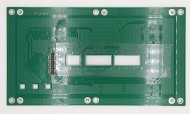

MEMBRANE SWITCH&LEXAN

Button-Fly Industry gives you personalized and prompt service for all of your membrane switch keypad needs. From quick turn prototypes to large production orders, we will deliver

you a quality membrane switch solution on time.

Our design expertise is strong in medical, scientific, aviation, and defense. When you partner with Button-Fly Industry you control the design process. We use high quality design source

files and documentation to go with every job. We can design your interface with electronics, overlay, lighting and mechanicals. We can also design a part of the interface or consult with

you on an existing design.

We can deliver your first articles within one week of receipt of a purchase order on silver circuits. Copper flex circuits require a 3-4 weeks lead time.

Our Capabilities:

Membrane Switch Keypad

Graphic Overlay/LEXAN

Flexible Printing Circuit/FPC/FFC

Nameplate series

Keypad metal domes

Acrylic/PC panel with silscreen printing

MEMBRANE SWITCH & LEXAN EXHIBITION

METAL MACHINING

Quality is the enterprise life

A good and guaranteed quality involved many factors and aspects. Button-Fly Industry metal factory have equipped the high-end machining equipment, such as MAKINO machining center, WAIDA optical grinding, MITSUBISHI wire cutting machine, SODICK mirror CNC sparking machine, NIKON tool microscope, NIKON projector etc. And the technical personnel are with years of experience in machining precision parts average above 5 years. Furthermore, Button-Fly Industry quality team will check it after every machining step is finished, to make sure every step is right and all process are under specification. Of course, the material is most important as well, all the material selection will follow customer's requirement and provided the COC from the material manufacturer. Those steps make us confidence to take your most challenge projects.

A good and guaranteed quality involved many factors and aspects. Button-Fly Industry metal factory have equipped the high-end machining equipment, such as MAKINO machining center, WAIDA optical grinding, MITSUBISHI wire cutting machine, SODICK mirror CNC sparking machine, NIKON tool microscope, NIKON projector etc. And the technical personnel are with years of experience in machining precision parts average above 5 years. Furthermore, Button-Fly Industry quality team will check it after every machining step is finished, to make sure every step is right and all process are under specification. Of course, the material is most important as well, all the material selection will follow customer's requirement and provided the COC from the material manufacturer. Those steps make us confidence to take your most challenge projects.

Our Capabilities:

Saw-cutting, Cross-cutting

CNC Machining

CNC Lathe

EDM/WEDM Machining

Grinding Machining

Surface Treatment as below

Sandblasting, Brushing, Polishing plus Anodize, Surtec 650, Trivalent Chromate